Improving Quality Assurance with Automated CMMs

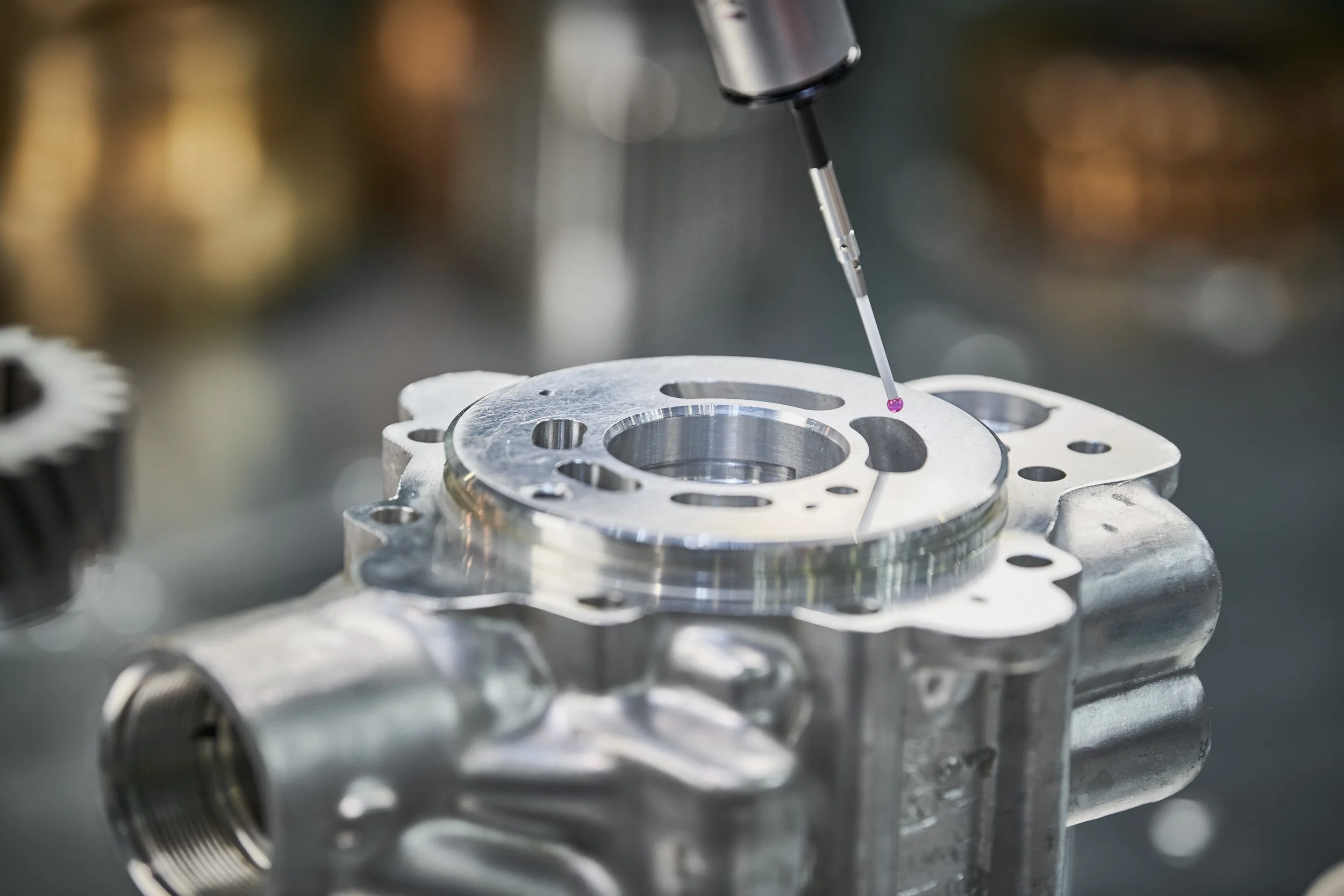

Alard Engineering is proud to maintain our status as technology leaders with the highest industry quality standards. One way our AS9100 machining shop upholds this reputation is by using automated coordinate measuring machines (CMMs).

The risk of measuring geometric parts without an automated CMM is great. For example, if it takes a CNC machine shop eight weeks to reach final inspection, and the first pass yield rate is low, there's a problem somewhere. The parts must be scrapped, and the process must start over. The shop has not only wasted effort and money but also upset the customer by extending the lead time.

At Alard Engineering, automated CMMs prevent this scenario by catching variances early, minimizing waste, and optimizing production.

The Benefits of Automated CMMs

An automated CMM makes it much easier and faster to get accurate measurements on parts with complex geometries during the manufacturing process. With this equipment, the Alard Engineering team can check parts more frequently, identify production issues sooner, and get quality parts to our customers on time.

Our CMMs can also handle various parts sizes. We use Brown & Sharpe XCEL 7.10.7, BRIDGE DCC machines with 28" x 35" x 23" specifications. Combining this top-of-the-line equipment with the world's leading measurement software, PC-DMIS, allows us to offer the gold standard in quality inspections.

Advantages over Manual Measuring

Manual inspections with tools such as gauges and calipers are time-consuming and lack precision. The more complex the part is, the longer it takes to measure it, and the less accurate the results are. You reach a point with manual measuring where the number of dimensions, the complexity of angles, and the tightness of tolerances are too complicated.

Even using a manual CMM doesn’t guarantee precision. When a part has a high degree of complexity, it’s very challenging if not impossible to get precise measurements from a manual CMM. Our Alard Engineering team has used manual CMMs in our AS9100 machining shop that produced inaccurate readings. We’ve learned from experience that automated CMMs are the best solution.

An In-Depth Inspection Process

Automated CMMs enable an in-depth inspection process, which includes first article inspection, in-process inspection, outside-process inspection, and final inspection. This equipment helps our team check geometric parts from the beginning to the end of the production cycle, saving customers time and money with increased accuracy and enhanced first-pass yield.

At Alard Engineering, we want our first pass yield to be the lowest at first article inspection and the highest at final inspection. Automated CMMs help us achieve that goal by detecting issues in the production cycle early. With better results from the start instead of toward the end, we conserve the labor and financial resources it would take to amend those issues later.

Automated CMMs Improve Quality, Speed, and Efficiency

Automated CMMs significantly improve every aspect of our inspection process compared to manual tools and CMMs.

Our Alard Engineering team is committed to embracing technological advancements and delivering precision results as part of our world-class aerospace and American defense manufacturing services.

Request a quote from our AS9100 machining shop today.